In the quest for cleaner and more efficient energy storage solutions, Lithium Iron Phosphate (LiFePO4 or LFP) batteries have emerged as a promising contender. These batteries are renowned for their high safety, long cycle life, and impressive thermal stability. At the heart of LFP batteries lies a carefully crafted material composition, which plays a pivotal role in their exceptional performance. In this article, we'll explore the chemistry and composition of LFP batteries, shedding light on the elements and mechanisms that make them a vital component of the energy landscape.

LFP batteries belong to the family of lithium-ion batteries, which have become ubiquitous in our daily lives, powering everything from smartphones to electric vehicles. However, LFP batteries have garnered significant attention for several reasons:

The exceptional characteristics of LFP batteries are closely tied to their material composition, particularly the cathode (positive electrode) material. Let's delve into the chemistry and elements that make up the LFP battery's composition:

To enhance the electrical conductivity of the LFP cathode, conductive carbon additives are often incorporated. These additives provide a network for electron transfer within the cathode material, allowing for efficient charge and discharge.

Binders are used to hold the cathode material together in a compact and stable form within the battery cell. The electrolyte, typically a lithium salt dissolved in a solvent, serves as the medium through which lithium ions travel between the cathode and anode.

A separator, typically made of a porous polymer material, physically separates the cathode and anode while allowing lithium ions to pass through. It prevents short circuits within the battery cell.

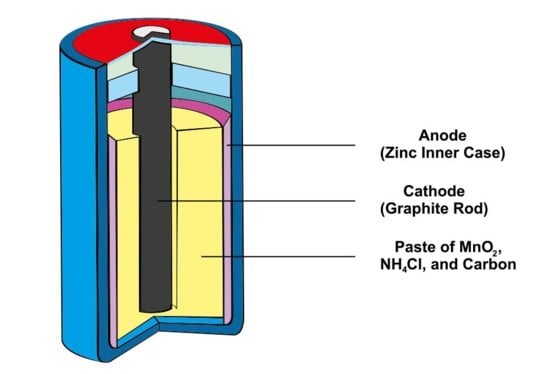

While the cathode material in LFP batteries is primarily lithium iron phosphate, the anode typically consists of graphite or other carbon-based materials. During charging, lithium ions are extracted from the cathode and intercalated into the anode material. This process is reversed during discharge.

The chemistry of LFP batteries involves several electrochemical reactions that occur during charging and discharging cycles. Understanding these reactions is essential to grasp how LFP batteries function:

Oxidation Reaction (Charging):

During charging, lithium ions (Li+) are extracted from the cathode (LFP) and move through the electrolyte to the anode (graphite), where they are intercalated into the graphite structure. This process results in the movement of electrons (e-) from the cathode to the anode, creating an electric current.

Reduction Reaction (Discharging):

During discharging, the stored lithium ions in the anode (graphite) move back to the cathode (LFP). This process releases energy and powers external devices or systems.

LFP cathodes are known for their distinctive crystal structure, which plays a crucial role in their performance. The crystal structure of LFP is characterized by an orthorhombic lattice, and it features well-ordered channels for lithium ion migration. This crystal structure contributes to the high structural stability and longevity of LFP batteries, making them resilient to the stresses of charging and discharging cycles.

LFP batteries have gained popularity in various applications due to their unique material composition and characteristics:

LFP batteries are often touted for their environmentally friendly characteristics. The use of iron and phosphate, which are abundant and less expensive compared to cobalt and nickel, can lead to reduced environmental and supply chain concerns. Additionally, their long cycle life and recyclability make them a sustainable choice for energy storage.

The material composition of Lithium Iron Phosphate (LFP) batteries is a testament to the elegance of chemistry in energy storage. With lithium, iron, and phosphate as its core constituents, LFP batteries have emerged as a compelling choice for a range of applications, from electric vehicles to renewable energy storage. Their safety, longevity, and cost-effectiveness are transforming the energy landscape, contributing to a cleaner and more sustainable future. As research and development continue, LFP batteries are poised to play an even more significant role in the global transition to cleaner and more efficient energy solutions.