The rapid advancement of electric vehicles (EVs) and the increasing demand for energy storage solutions have spotlighted the importance of battery technology. Among the various battery chemistries, Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) batteries are two prominent contenders, each with its unique set of advantages and limitations. This article delves into the differences between LFP and NMC batteries, offering insights into their chemistry, performance, environmental impact, and applications, ultimately shedding light on their roles in shaping a sustainable energy future.

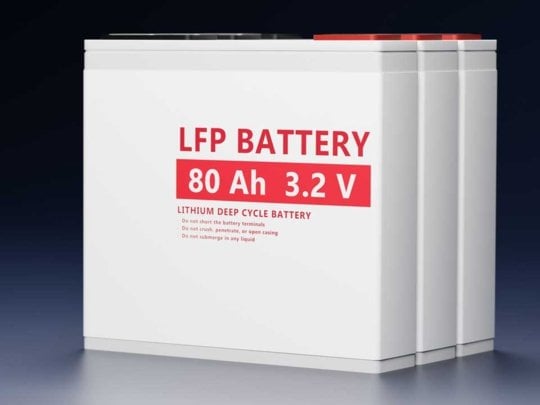

Lithium Iron Phosphate (LFP) batteries, often referred to as LiFePO4 batteries, are a type of lithium-ion battery that utilizes lithium iron phosphate as the cathode material. LFP batteries are known for their stability and safety due to their robust chemical structure.

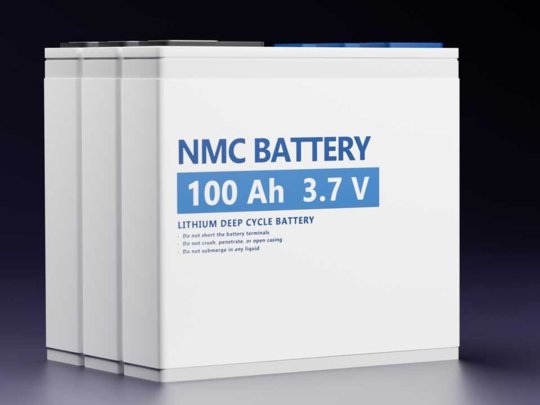

Nickel Manganese Cobalt (NMC) batteries belong to the family of lithium-ion batteries and are widely used in various portable electronics and electric vehicles. They are known for their high energy density, which allows for a compact and efficient energy storage solution.

Now that we have explored the key characteristics of LFP and NMC batteries, let's compare them in various aspects:

The choice between LFP and NMC batteries depends on the specific requirements of the application. Here's a closer look at where each battery type excels and their potential future prospects:

Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) batteries are two prominent lithium-ion battery technologies, each with its unique set of characteristics and advantages. LFP batteries are known for their safety and long cycle life, making them suitable for stationary energy storage and electric buses. NMC batteries, on the other hand, offer high energy density, making them a preferred choice for electric vehicles and consumer electronics.

The choice between LFP and NMC batteries ultimately depends on the specific needs of the application, including safety, energy density, cost, and environmental considerations. As the energy storage landscape continues to evolve, ongoing research and development are likely to lead to improvements in both battery types, addressing their respective limitations and expanding their range of applications. In the quest for a sustainable energy future, the choice between these two battery chemistries plays a crucial role in shaping our journey toward cleaner and more efficient energy solutions.