Vacuum hardening furnaces are used in industrial sectors such asaviation, aerospace, energy, tooling, die and mold, automotive, medical industries and heat treatment companies.

AICHELIN offers solutions for vacuum heat treatment in full compliance with international standards such as AMS 2750, ASTM, NADCAP, NADCA CQI-9 etc.

Options including:

EXTENDED LIFETIME AND RELIABILITY

Achieve an extended lifespan with consistent, reproducible results, ensuring reliable performance over time.

USER-FRIENDLY DESIGN

Benefit from easy operation and maintenance, enhancing user experience and reducing downtime.

ENERGY EFFICIENCY

Maximize energy efficiency with advanced insulation and a cold wall design that minimizes surface losses.

RAPID HEATING AND COOLING

Rapidly heat and cool both small and heavy charges, reducingcycle times, improving process efficiency and throughput.

PRECISE PROCESS CONTROL

Perform accurate process cycles using both furnace and load thermocouples for precise temperature control.

LOW MAINTENANCE COSTS

Utilize the optimized furnace design based on years of experienceto ensure low maintenance costs combined with efficient performance.

FULL COMPLIANCE

Compliant with applicable international standards such as CQI-9, NADCA, NADCAP, AMS 2750 etc.

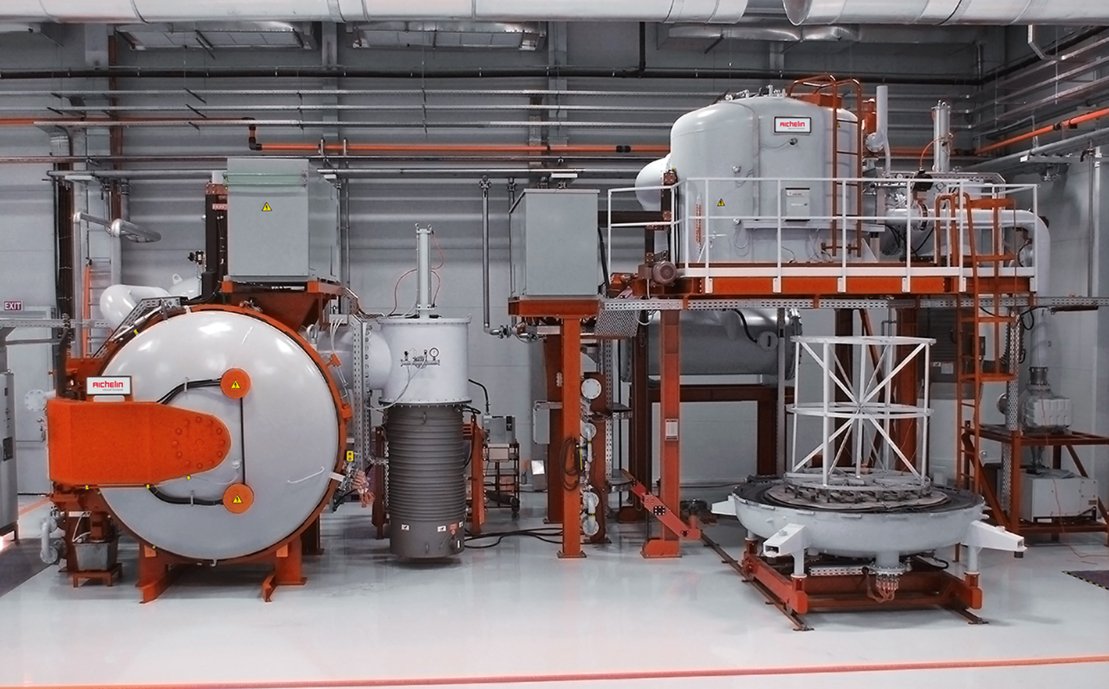

AICHELIN direct heated vacuum tempering furnaces deliver excellent temperature uniformity, rapid heating and cooling performance in a single-chamber design. In order to achieve a clean surface of quenched parts after tempering the furnace is designed to ensure the necessary parameters for the desired surface quality. Deeper vacuum levels allow moreflexibility for various heat treatment applications like aging of aircraft engine parts. AICHELIN vacuum tempering furnaces can process a wide range of materials and different processes like ageing, annealing or stress relieving.

Vacuum Furnaces

(PDF |

2.10 MB |

ger-DE )